The warship Vasa to be supported with Swedish steel from Alleima

2025-01-28

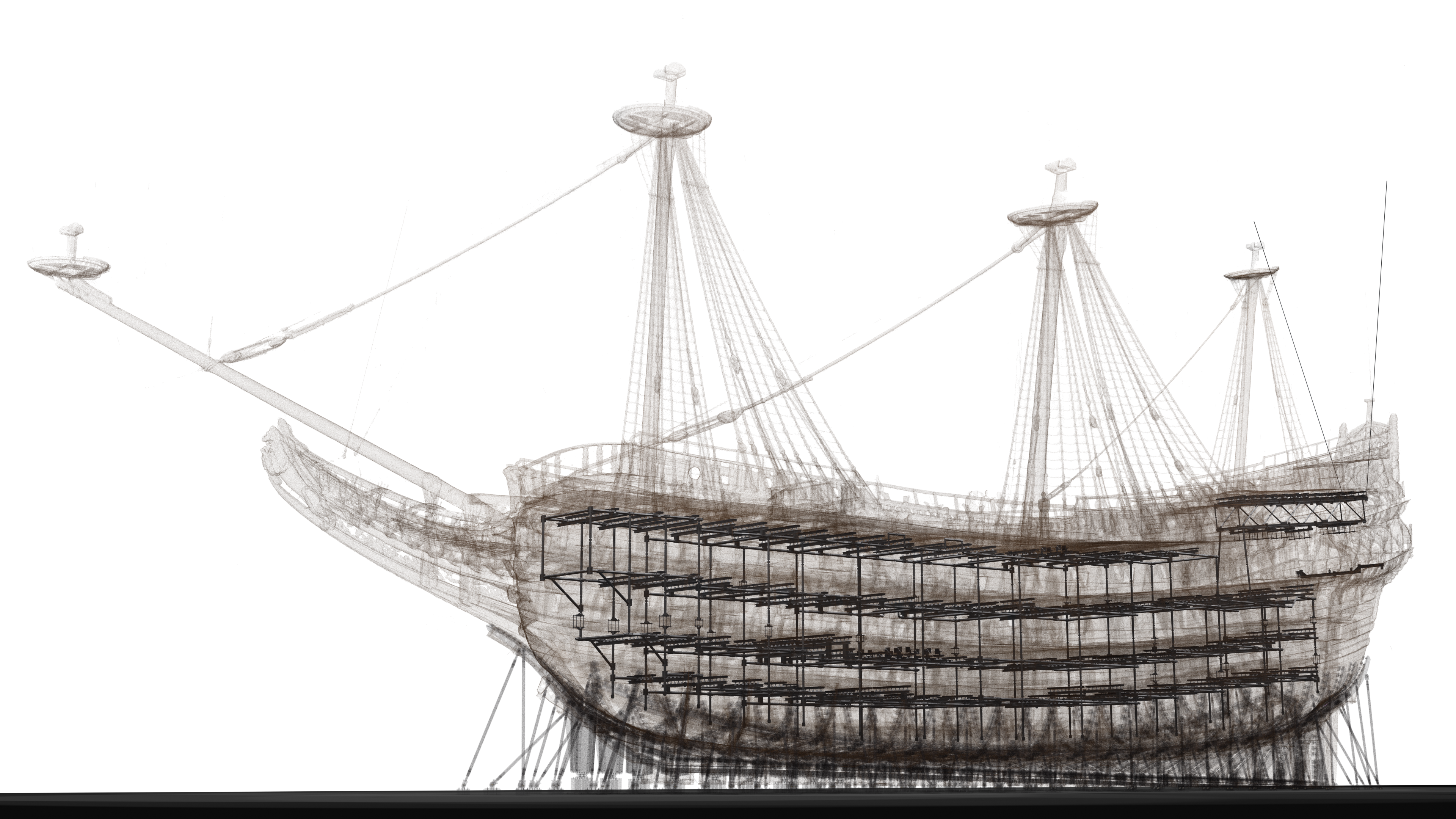

The warship Vasa is on the move. While the movements are very small, they could have enormous consequences over time. At the same time, the ship’s wood has weakened. The solution is to build a completely new support structure, a more advanced and durable structure that will protect the ship against the deformations currently caused by the ship’s own weight and natural movements. But that is not enough. This is why an internal support, in the form of a steel skeleton, is being installed in the ship.

“The internal support will run from the keel all the way up to the upper deck. It will help bear the loads from the deck and deck beams to slow the downward movement of the hull. To do this, the skeleton needs to be made of a material that is both strong and lightweight,” says Magnus Olofsson, Project Manager of Support Vasa.

The internal steel skeleton will be built as a truss with tubes. This solution stabilises the hull, slows down the ship’s movements and distributes the load. Among other benefits, the collaboration with Alleima allows the internal skeleton to be lighter thanks to the use of a special steel developed by Alleima.

The support structure is made of an advanced stainless steel with exceptional strength and very high resistance to corrosion: SAF™ 2507 super-duplex, produced in Sandviken.

“Alleima’s advanced stainless steel and speciality alloys are found in the world’s most demanding environments and applications. It has superior strength, which means that less material is needed, reducing the weight of the steel skeleton. Its corrosion resistance allows the material to come into direct contact with the ship without rusting. In addition, it is produced using fossil-free electricity and consists of 80 percent recycled steel. This not only helps in the preservation of Vasa, but also reduces environmental impact,” says Tom Eriksson, Head of Research at Alleima.

“We are proud to be part of ensuring that Vasa is preserved for the future. This historic project reflects our commitment to innovation, sustainability and Swedish cultural heritage. The project is unique in both implementation and procurement, and illustrates the power of long-term partnerships between the business community and cultural institutions,” says Elja Nordlöf, Director of Communications at Alleima.

In summary, the new support structure will ensure that the warship Vasa is supported in order to slow down movements in the hull, minimise the risk of crack formation, and ensure that it retains its existing shape. All so that the ship can be preserved far into the future. The complex work was preceded by more than ten years of research and advanced testing.

“Thanks to the unique properties of the material and the materials expertise available at Alleima, there will be less damage to Vasa’s hull. One estimate is that we only need to drill about half as many holes in the hull as would otherwise have been necessary. This is incredibly important to us from a preservation perspective,” says Magnus Olofsson.

FACT BOX – THE SUPPORT VASA PROJECT

The support structure that has been holding Vasa since the 1960s needs to be replaced, as it is damaging the ship and causing deformations in the hull. This is due to the weakening of the ship’s wood. The entire support structure is being replaced over a number of years. Construction began in April 2024.

The 17 external braces currently in place will be replaced with 27 cradles, with a joint under the keel. This will result in the ship being supported at a greater number of points compared to today. Once everything is complete, the external support will be supplemented with an internal support, similar to a skeleton. The internal support will run from the keel all the way up to the upper deck. It will help bear the loads from the deck and deck beams to slow down the movements in the hull. Alleima is sponsoring the Vasa Museum with all the steel needed for the internal support.

With the specialised knowledge and special alloy that Alleima brings to the project, the collaboration makes it possible to produce an internal skeleton that is lighter than originally envisaged.

The sponsorship collaboration between the Vasa Museum and Alleima has been procured under the Swedish Public Procurement Act, and will last for five years.

For further information, pictures and videos, please contact:

Catrin Rising, Communications Officer for the Support Vasa project

Telephone: 0737-35 16 02

E-mail: catrin.rising@smtm.se